Overview

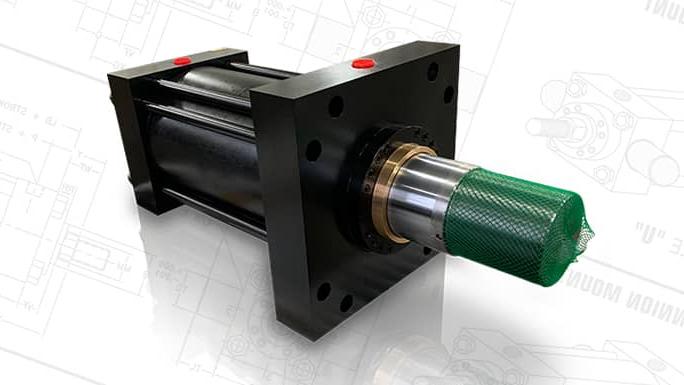

Our H6 steel tie rod hydraulic cylinder is built to handle the most rugged applications and is in high demand for clamping, stamping, forging, bending, tilt and shearing processes.

- Bore Sizes From 1.5" - 24" 3,000 PSI

- 20 mounting styles

- JIC-NFPA Interchangeable

- 3 Year Limited Warranty

- Manufactured in Michigan

Common Industries:

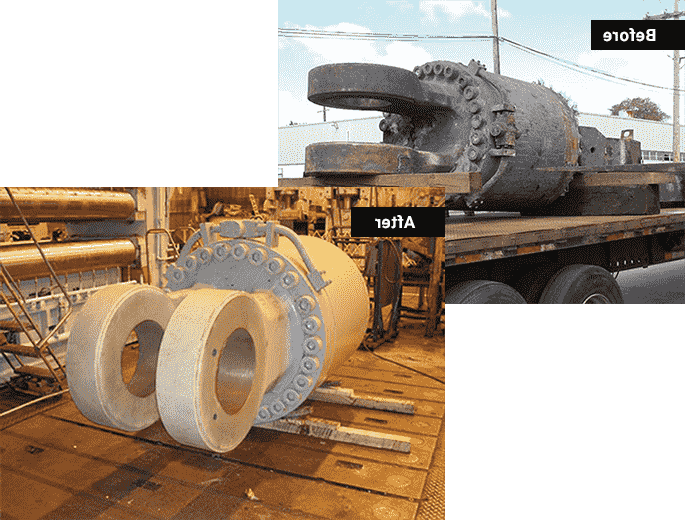

These steel tie rod cylinders are built to last in the most rugged applications for example foundry, steel mills, stamping, plastics, paper and pulp, just to name a few.

Common Applications:

Clamping, stamping, forging, bending, tilt and shearing

Product Resources: